Are net-zero developments unachievable or can hemp win over objectors

The amount of carbon ‘built-in’ (pardon the pun) to one new home is equal to approximately 50 or more transatlantic flights. So is the answer to build less, or to change building materials?

Firing bricks is very carbon-heavy. Making concrete is less so, but the chemical process involved in concrete creates carbon dioxide as a by-product. Internationally, cement production accounts for as much as 7% of global CO2 emissions, which is three times the emissions produced by aviation. Accoring to Valerie Masson-Delmotte, a key contributor to the UN's Intergovernmental Panel on Climate Change, “That's more than all the emissions from the European Union or India, just behind those of China and the US". Such figures reinforce objections to development, creating a difficult headwind for those fighting appeals.

Reducing carbon emissions in developments – is hemp the answer?

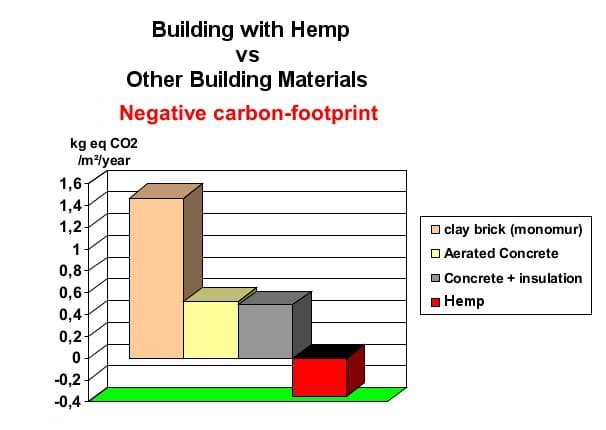

The drive for zero carbon can give planners a headache, but could hemp be part of the answer? This new building material has excellent insulation properties and provides carbon sequestration (CO2 storage) for the building’s lifespan. This means hemp has a negative carbon footprint as shown below:

Is it too late at appeal stage to change construction materials if carbon emissions emerge as an issue?

Hemp may be prove to be useful in addressing carbon concerns at an early stage in designing a development or when addressing a LPA’s objections to a development, but is it too late to consider it when a proposal is already at appeal? In fact it’s perfectly reasonable for the appellant to give the Inspector the option, should the Inspector consider it necessary, to impose a planning condition regarding approval of construction materials. Such a last-minute retrofit to the proposals may just help tip the appeal where an Inspector's Decision is hanging in the balance.

For example, the appellant may give a written commitment to the LPA they would swap all breezeblock & render in the construction for hempcrete & render, thereby greatly reducing the carbon footprint of the construction phase. Depending on the original specifications, swapping to hempcrete may also improve insulation and thereby reduce carbon emissions throughout the building’s lifespan. Details of the building materials and/or an emissions assessment can be dealt with at a later date through conditions.

One example of such an appeal can be found in an Inspector's Decision on 15/6/22 allowing an appeal against Teignbridge District Council who had refused reserved matters for 22 dwellings on grounds including, “The effect of the proposed development with regard to carbon emissions” (appeal ref: 3283046). The Inspector noted, “the Local Plan requires proposals to seek to minimise their carbon footprint both during construction and in use….and given that it would be necessary to ensure that measures could be incorporated into the development without the potential need for redesign during construction, it would be reasonable and necessary that that matter be secured by a pre-commencement condition.”

In allowing the appeal, the Inspector imposed a condition requiring full details of carbon reduction measures to be submitted to the LPA to demonstrate how the development will minimise its carbon footprint and achieve a reduction in CO2 emissions of at least 24% reduction in emissions over Building Regulations Part L2A 2013.

The Climate Emergency reflected in the NPPF

“Moving to a low carbon economy” is one of the environmental objectives in paragraph 8c of the National Planning Policy Framework, with NPPF Chapter 14 expanding on the topic. Paragraph 152 notes, “The planning system should support the transition to a low carbon future in a changing climate,...(and)...shape places in ways that contribute to radical reductions in greenhouse gas emissions...” As the NPPF is a material planning consideration, an Inspector has the scope to weigh carbon emissions as a factor in any appeal.

Carbon emissions policies in Local Plans

Many LPs now include policies which seek to reduce carbon emissions, reflecting any Councils’ desires to go beyond Building Regulations in a race to be seen to be Green. This trend is being reflected in appeals with Inspectors increasingly being asked to consider the carbon emissions of the development.

Policies generally refer to (1) the development’s ongoing energy requirements and (2) the carbon footprint of the construction project itself. For a discussion about designing-in renewable energy infrastructure see a previous blog. Here I concentrate solely on reducing the carbon footprint of the build itself.

Hemp as a eco-friendly construction material

At the Farm Business Innovation Show in the NEC in Birmingham a few years back I was surprised to see hempcrete blocks which look like breezeblocks, but have many advantages over them:

• High insulation properties;

• Breathable, fireproof and healthy (hemp is naturally antibacterial and inert);

• Relatively cheap;

• Can be sprayed-in to whatever wall shape is required;

• Hemp absorbs carbon as it grows, making the product carbon negative;

• Unlike timber which takes decades to grow, hemp takes only 4-5 months from planting to harvest.

Unlike cannabis, hemp can be grown completely legally in the UK, albeit under licence. In fact under Henry VIII all farmers in England were required by law to grow hemp, in order to supply the navy with enough raw material to make canvas sails (canvas and cannabis derive from the same root word).

Hemp grows very easily in the UK and requires no fertilisers or pesticides. Industrial hemp fibre is grown commercially in over 30 countries with diverse climates, from China to Chile, and Switzerland to Spain, for textiles, animal bedding, paper making and building purposes. Hempcrete was used in constructing the Marks & Spencer store at Cheshire Oaks in North West England and in the Suffolk-based brewery Adnams’ distribution centre, as well as being used over the past two decades in many housing projects across the UK.

More details about using hemp in UK building projects can be found at on the Hempcrete Network website and on the Alliance for Sustainable Building Products website. Also useful are the UK Hempcrete sites EastYorkshireHemp, Hempblock and UKHempcrete. The hempcrete manufacturer Isohemp in Belgium also has useful information about hempcrete products. I can also recommend a series of great videos about the use of hemp to reduce the construction sector's carbon emissions on Hemspan's LinkedIn pages.

Will hemp move construction from being part of the problem to being part of the solution?

Hempcrete blocks are emerging as the greenest building material currently available and could go a long way towards addressing objections about carbon emissions in new developments, according to the sources quoted above. It may prove a bit of a miracle cure for planners' headaches in relation to carbon emissions.